C Channel steel Roll Forming Machine

Basic Info

Model No.: KYT

Product Description

C Channel steel Roll Forming Machine

This c channel steel roll forming machine is cutting by the fly saw system . The thickness of the raw material is 1-3mm . The size of c purlin is 80-300mm . We change the size by changing the spacer .

Compared with the hydraulic cutting system , the fly saw system can cut any size of the c purlin , no need to adjust the blade .

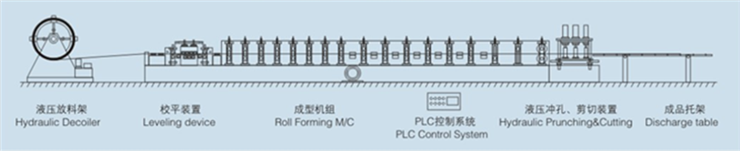

C Purlin Producting Process Flow

Decoiler -- Feeding and Leveling device -- Main Roll Forming System -- PLC Control System -- Hydraulic Punching and Cutting device -- Discharge table

Machine Parameter

Raw Material

A. Suitable Material: Colored Steel Plate, Galvanized Board, Aluminum Plate;

B. Width of the raw material: 175-465mm;

C. Thickness: 1mm - 3mm;

Main Body

A. Roller station: 14 rows;

B. Diameter of shaft: ¢80mm, 45# steel;

C. Roller material: 45# steel;

D. Frame: 350 H steel;

E. Operate: Manual and Automatic;

F. Working speed: 8 - 12 m/min;

G. Size (L*W*H): about 8700*1200*1600 mm;

Power

A. Motor power: 11 Kw, Hydraulic power: 7.5 Kw;

B. Voltage: 380V 50Hz 3Phases or Customization;

C. Driving way: 1.5 inch Chain

Components Of Machine

Manual Decoiler

It is uesd to support the steel coil and uncoill it in a turnable way. Loading capacity: 1.2T , Inner diameter: 300-500 mm.

Feeding Table and Leveling Device

Feeding Table: It is used to control the width and position of the steel sheet. The sheet is guided into the machine with correct position, to make sure the panel is neat and parallel.

Leveling device: It used for making the material flat before feeding into the roll forming machine.

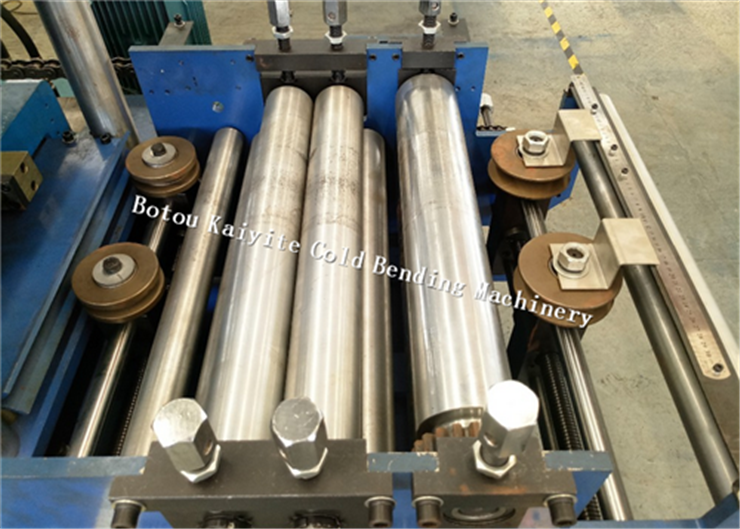

Main roll forming system

The roller surfaces is polishing and hard plating, the polished and heat treatment towards the molds also can keep the molding plate surface smooth and not easy to marked when it is being stamped.

Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

PLC Control Cabinet

The target piece's length is adjustable and digit of it can be adjusted. This computed mode has two type, one is manual, the other one is automatic. So you can operate it by any mode that you want to.

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the length and cut the target products. Material of blade: Cr12, quenching treatment.

Discharge table

It adopts welded steel and supported roller to transmit the products, which is uesd to collect the finished products. The length of this discharge is 6 meters.

Spare Part

One box for free.

Production Process

The following picture shows the whole production process of the roll forming machine.

FAQ

Q1. What`s your delivery time?

A1: Depending on the type of machine, duration of 15 days to 60 days from the date of contract.

Q2. Do you have after-sales support?

A2. Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machine running in order to keep our business running.

Q3. What will you do if the machine is broken?

A3. Our machine`s warranty is 18 months. During the warranty period, if the broken parts can`t repair, we can send the new parts replace the broken parts freely, but you need pay the express cost yourself. If it is beyond the warranty period, we can supply the technical support for the whole life of equipment.

Q4. Can you be responsible for transport?

A4. Yes, please tell me the destination port or address. We have rich experience in transporting.

Contact us if you need more details on C Channel Steel Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about C Channel Forming Machine、C Steel Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : C / Z / U Purlin Roll Forming Machine > C Purlin Roll Forming Machine